January 5, 2024. Actually building stuff!

This is 2024 and time to transition from "Ugly" to a more refined method of building stuff. The tools are here so why not use them?

There is a certain charm and bravado to building rigs using the methods employed early on in our hobby. We all envision ourselves like "Arnie" (Schwarzenegger) storming a position holding an M-60 machine gun in our left hand while punching out a guy with our right hand. This is akin to using Manhattan glue down pads and a chunk of wood for a base.

But today we have at our disposal Surface Mount parts which are rapidly becoming the only parts available. So time to man up and make the move to more current fabrication trends. Sure go ahead and make at least one Manhattan board so you can say been there and done that and then hang it on a wall as a piece of art to be admired.

Building stuff today has two components with the 1st being the parts themselves and the 2nd piece is the tools that we will use.

Surface mount parts are in many cases the only parts you can buy and for many IC's now only come in SMD. Depending on your eyesight the 805 parts are OK to work with but you might want to head for the 1206 size. In any case you will need a head band magnifier and various sizes of tweezers.

As to part #2 think of outside PC Board suppliers. I have heard from many hams who use PC Board processing companies. Many are in China . As long as you supply the design and if the area is small (2X4) you can get several boards in short order for about $10. That said if you screwed up the design you may have to cut another order and more time to get the correct boards.

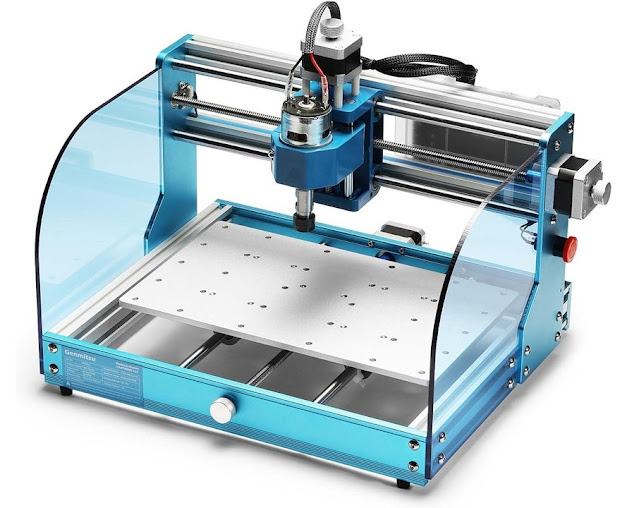

CNC milling of PC Boards, a better option, is not complex as the hobby aspect has caused a shift in the machines available from production capable to hobbyist use. Ease of use has been a driving force. The prices are astonishing -- read low cost. A year ago this machine was over $300 and now just over $200.

Try building that jewel using glue down Manhattan pads. You might have some difficulty!

The advantages of CNC Milling are many but just so you know.

- Repeatable Circuitry -- you want another board just punch the Start button

- Short Direct Connections to avoid shorts and unwanted feedback paths. BTW this board above uses size 805 parts. See if you can spot the unnamed 680 Ohm Resistor.

- Cost factor -- many Surface Mount parts bought in bulk cost pennies and with the entry cost of the machine being about $200 -- you have a win win. Bulk qualifies with as little as 25 pieces.

- Compact construction. Today with POTA, GOTA, SOTA and IOTA, the call is for compact light weight gear. A guy recently said he was IOTA - Island on the Air. He was at an abandoned gasoline station operating from an empty fuel island. He had a 4 Call and was from one of those southern states. He sounded like he started cocktail hour at 9 AM.

- Fixing problems is easily done and a new board can be created with very little effort -- when fixed, just punch the start button.

- Front panels with engraving can be done at home and custom to your needs. Like Below

Three D printing is another tool just like the CNC Machines and you see custom cases being printed or perhaps custom knobs. A ham friend who is into astronomy needed a custom gearing system so his telescope could track a star for photographing its movement. For a commercial system you would need a home loan but he did it for about $1K including the 3D Printer.

The printers are much like the CNC Mills, as their cost has come way down --AND if you can do the CNC the process, it is similar to what you need to do for the 3D Printer.

At least start looking at the new technology tools available at prices that can fit a larger share of the ham population budgets.

Of the estimated 7700 US hams (1% of the total licensed US hams) that homebrew their rigs, how many have Nano VNA's? That number may be quite high and beyond 80%. An real Nano VNA will set you back about $100. (That is what the 2nd one that works cost me). For another $100 beyond the price of the Nano VNA you can have a CNC Mill. Get out the plastic and get moving!

73's

Pete N6QW